Boronizing - Heat Treatment

Boronizing (boriding) services create ultra-hard, wear-resistant surfaces on steel components for high-temperature, high-wear environments. Contact us to discuss your project and request a quote.

Wear Protection by Boriding

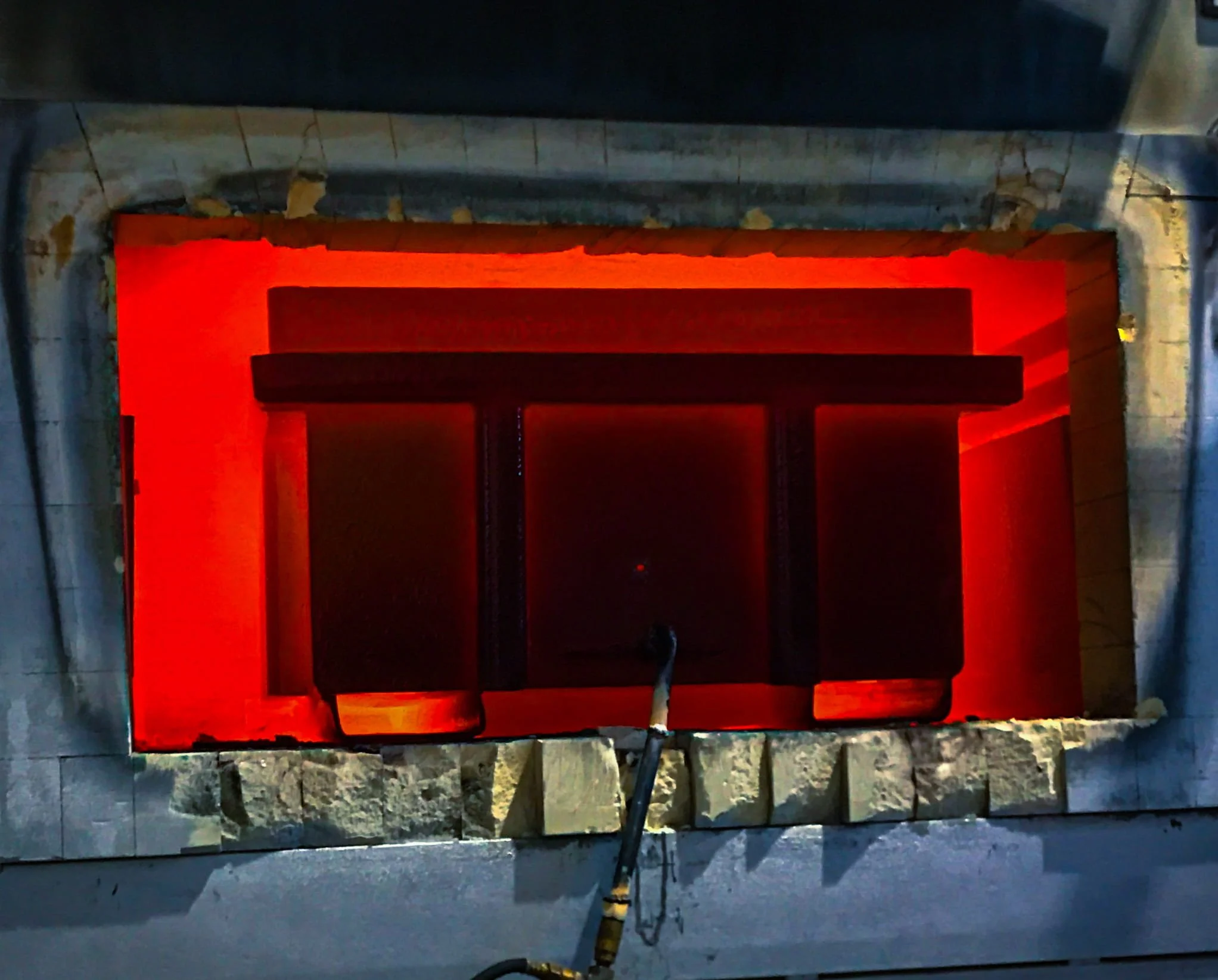

Boriding (boronizing) is a thermochemical diffusion process in which hard and wear resistant boride layers are generated by diffusing boron onto the surface of material. The treatment of the materials is carried out in a temperature range of 750 to 950°C. An essential element is the optimal distribution of heat in the furnace used in order to treat all parts of a batch evenly. During the boriding process, complex intermetallic compounds are created between the elements iron, boron, chromium, nickel, vanadium, etc. The resulting borides form a hard peripheral surface layer consisting of Fe2B and other compounds. Due to its crystalline structure, the boride layer is anchored exceptionally well to the base material.

MATRIXX III, our boronizing treatment process is dispensed in powder form. This boriding procedure is especially suitable for unalloyed and low alloyed steels. With increasing content of alloying elements, the diffusion rate and thus the thickness of the achievable boride layer decreases. At the same time, alloying elements such as nickel and chromium contribute to an increase in the hardness and wear resistance.

Boronizing Materials

The range of borideable materials is varied, ranging from cast iron, cast steel, and most steel grades to nickel-based alloys and special materials such as Stellite. Materials containing silicon and aluminum are not suitable materials for boronizing. Steels with correspondingly high levels of the elements mentioned can affect the boriding result.

Many properties can be improved by boriding. Thus, boronized surfaces are extremely hard and have a much longer service life compared to functional surfaces such as can be achieved, for example, by nitriding, carburizing, chrome plating, CVD or PVD coating.

The increased resistance to abrasive wear is accompanied by an improved resistance to cavitation. The reduced friction coefficient of boronized surfaces improves the lubricating properties and reduces wear. In the event of a lubricating film break, the boride layer provides excellent emergency running properties, even at high temperatures up to 1000 °C.

Boronizing is widely used in various industries; fittings, power plant technology, gear and transmission technology, textile machinery, pump construction, milling and crushing technology, oil/gas industry, extrusion technique, turbo-charging, agricultural machinery and power tools.

Boronizing Industries & Applications

Boronizing is widely used across many industries to enhance the wear resistance, hardness, and corrosion protection of critical components. Below are the main industries and examples of parts that most commonly receive boronizing treatment:

- Oil & Gas Industry → Wellheads, valve bodies, ball valves, and vavle seats, check valves and gate valves, tubing sections and couplings, and downhole components

- Gear and Transmission Technology → Gears and sprockets, shafts, bearing races, and transmission housings

- Pump Construction → Pump casings, impellers, sealing rings

- Milling and Crushing Technology → Crushing jaws, hammers, milling rollers

- Agricultural Machinery → Plowshares, cutting blades, wear plates

- Power Tools & General Hardware → Drill bits, cutting tools, nuts, bolts, and fastners

- Power Tools & General Hardware → Rollers, guides, and cutting blades

HARDNESS AND WEAR

LAB ANALYSIS

For specifics on how boronizing can help you, download the PDF below..

Lets Discuss Your Project

Need help finding the right solution? Contact us below or fill out the contact form and we will have the appropriate customer service specialist contact you.

Boronizing FAQs

-

Boronized parts have superior hardness (up to 2000 HV), increased wear resistance, improved corrosion resistance, and longer service life in abrasive or corrosive environments.

-

Our boronizing tray dimensions are 4' long, 2'3" wide, and 1' deep, making the process ideal for small- to medium-sized components such as gears, valves, pump parts, and cutting tools.

-

No, machining is not recommended after boronizing due to the surface's extreme hardness. Parts should be machined and finished to final dimensions prior to treatment.