Thermal Spray (Combustion) Coating

Thermal spray coating services deliver corrosion resistance, wear protection, and durable metallic coatings for industrial and marine applications. Located in Alberta, serving internationally, we have been the trusted applicators for industry leaders for over 35 years. Contact us to discuss your project and request a quote.

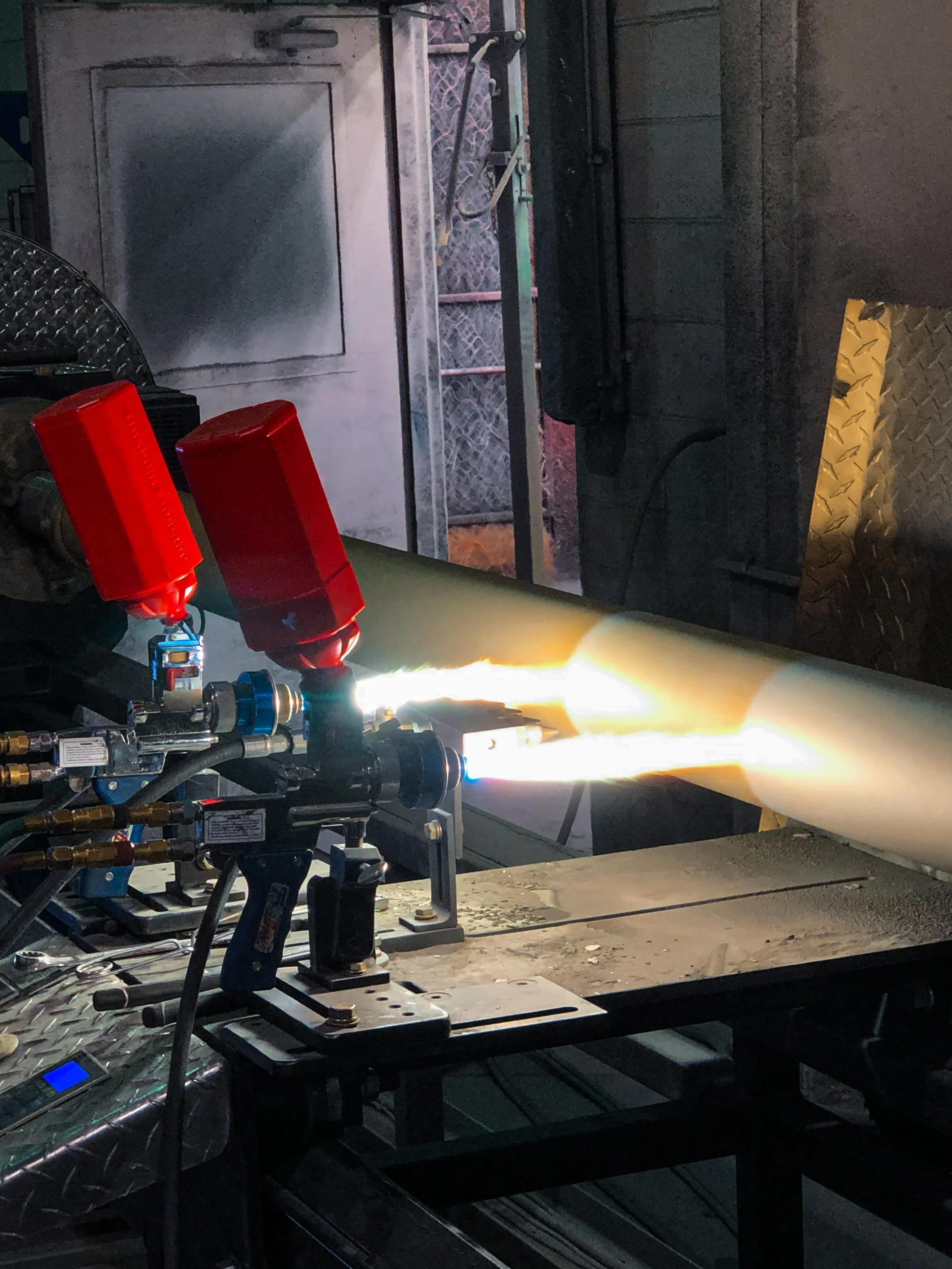

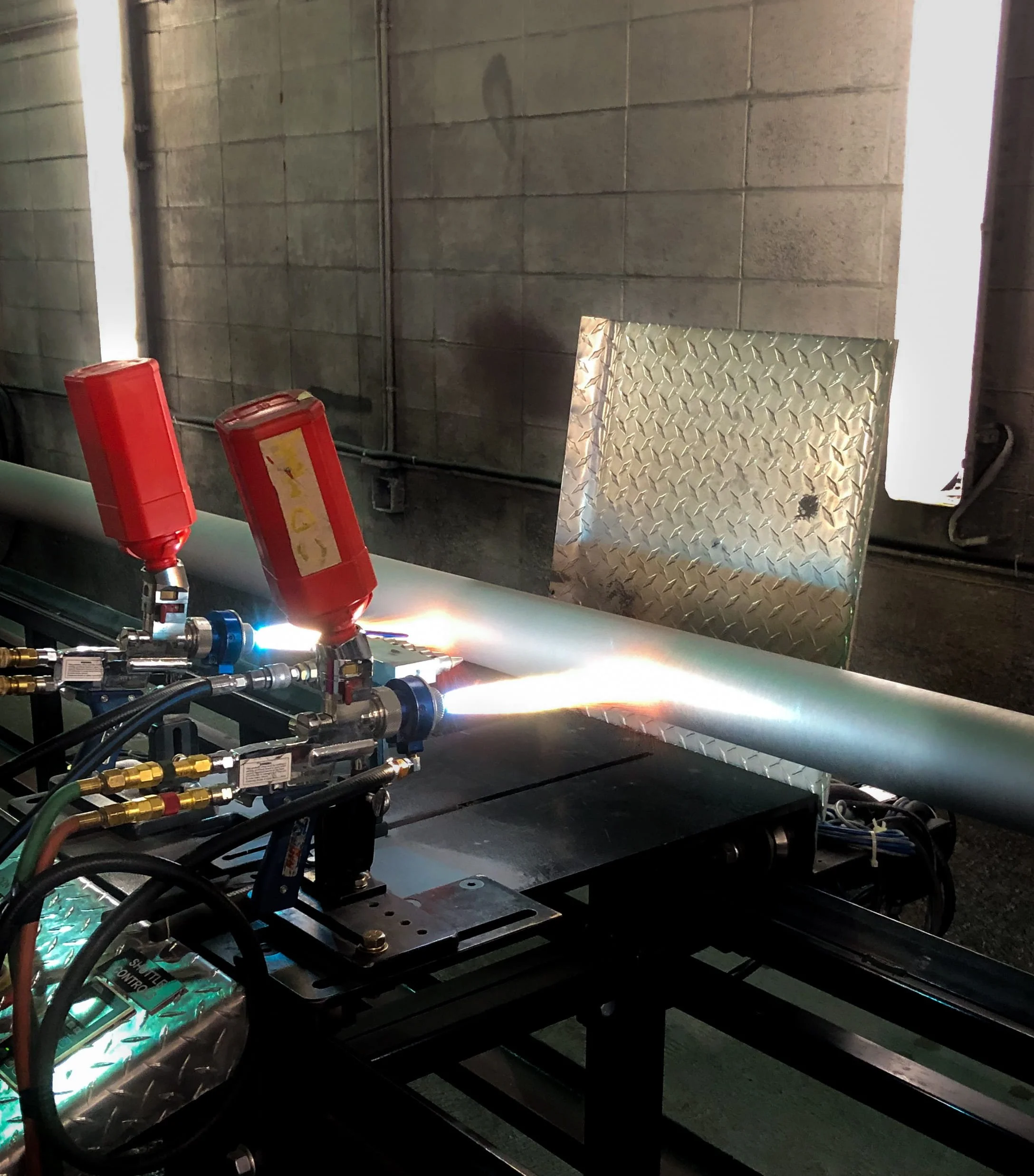

Combustion Powder Spray

Combustion spraying is a thermal spray coating process used to apply coatings that typically contain high levels of oxides and porosity together, with the option of achieving a rough surface finish. In the combustion spraying process, a gas stream produced by the chemical reaction between oxygen and a combustion fuel heats a consumable propelling it onto a substrate to form a surface coating. Backed by a customer-driven service, our facilities process a wide variety of component sizes to exacting standards with reliable, repeatable results. Combustion spray coatings offer the following benefits:

- Corrosion protection

- Wear resistance

- Heat and oxidation resistance

- Temperature management

- Electrical resistivity and conductivity

Metallic & Ceramics

Combustion spraying offers a cost effective alternative for applying metallic and ceramic coatings in a less demanding environment. The process relies on the chemical reaction between oxygen and a fuel of combustion to produce a heat source. The heat source creates a gas stream with a temperature in excess of 3,000°C with correctly balanced conditions between oxygen and acetylene. A consumable, usually a powder or wire, is heated and propelled onto a substrate to form a surface coating.

- Pump shafts/journals

- Seal areas

- Impellers

- Diffusers

- Housings

- Structures

Hastelloy

A nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments. The high nickel and molybdenum contents make the nickel steel alloy especially resistant to pitting and crevice corrosion in reducing environments while chromium conveys resistance to oxidizing media. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures. This nickel alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process application in an as welded condition.

- Excellent corrosion resistance in reducing environments

- Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

- High nickel and molybdenum contents providing good corrosion resistance in reducing environments

- One of the few materials to withstand corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Monel

Monel is a nickel-copper alloy (about 67% Ni – 23% Cu) which exhibits excellent corrosion resistance. Generally, its corrosion resistance is very good in reducing environments, but poor in oxidizing conditions. It is not useful in oxidizing acids, such as nitric acid and nitrous. Nevertheless, it is resistant to most alkalis, salts, waters, food products, organic substances and atmospheric conditions at normal and elevated temperatures. This nickel alloy is attacked in sulfur-bearing gases above approximately 700° F and molten sulfur attacks the alloy at temperatures over approximately 500° F. Monel 400 offers about the same corrosion resistance as nickel but with higher maximum working pressures and temperatures and at a lower cost due to its superior ability to be machined.

- Resistant to sea water and steam at high temperatures, salt & caustic solutions

- Good weld ability at high strength

- Low corrosion rate in rapidly flowing brackish or seawater

- Excellent resistance to stress-corrosion cracking in most freshwater

- Resistant to a variety of corrosive conditions led to its wide use in marine applications & other non-oxidizing chloride solutions

- Particularly resistant to hydrochloric and hydrofluoric acids when de-aerated

- Excellent resistance to neutral and alkaline salt

- Resistance to chloride induced stress corrosion cracking

- Good mechanical properties from sub-zero temperatures up to 1020° F

- High resistance to alkalis

- Virtually immune to chloride ion stress corrosion cracking in typical environments

Lets Discuss Your Project

Need help finding the right solution? Contact us below or fill out the contact form and we will have the appropriate customer service specialist contact you.