Industrial painting solutions designed to protect equipment from corrosion, wear, and extreme environments. Serving heavy industry within Alberta and Beyond with durable, high-performance coatings. Contact us to discuss your project and request a quote.

Industrial Painting in Alberta

About Our Industrial Painting

Industrial paint is among the most widely used and developed protective solutions in the world. These engineered coatings act as durable barriers that shield equipment and infrastructure from the harshest environments, significantly extending their service life while reducing replacement and maintenance costs. By applying the right industrial coating system, businesses can enhance durability, improve performance, and ensure safety across a wide range of applications.

Benefits of Industrial Painting Services

The advantages of industrial coatings go far beyond aesthetics. While they can improve the appearance of equipment, their primary function is protection. These coatings are designed to resist environmental, chemical, and mechanical stressors that would otherwise cause premature wear and failure. Some of the most important benefits include:

- Corrosion protection → prevents rust and microbiologically induced corrosion, especially in pipelines and marine structures.

- Hardness and durability → thermosetting systems create a tough finish that can withstand heavy loads and daily wear.

- Waterproofing and weatherproofing → protects both indoor and outdoor assets from water intrusion, extreme temperatures, and UV exposure.

- Abrasion and impact resistance → minimizes wear on moving components, extending equipment life.

- Chemical resistance → withstands contact with aggressive industrial solvents, fuels, and process chemicals.

- Thermal protection → certain coatings are engineered to resist heat, fire, and stress cracking.

- Cost-effectiveness → lowers maintenance and replacement expenses, providing long-term savings.

By serving as an engineered shield, industrial coatings paintings help companies maximize uptime, reduce operational risks, and improve the performance of critical infrastructure.

Common Industrial Painting Applications

Industrial painting is used across nearly every industry that depends on reliability and safety. Some of the most common applications include:

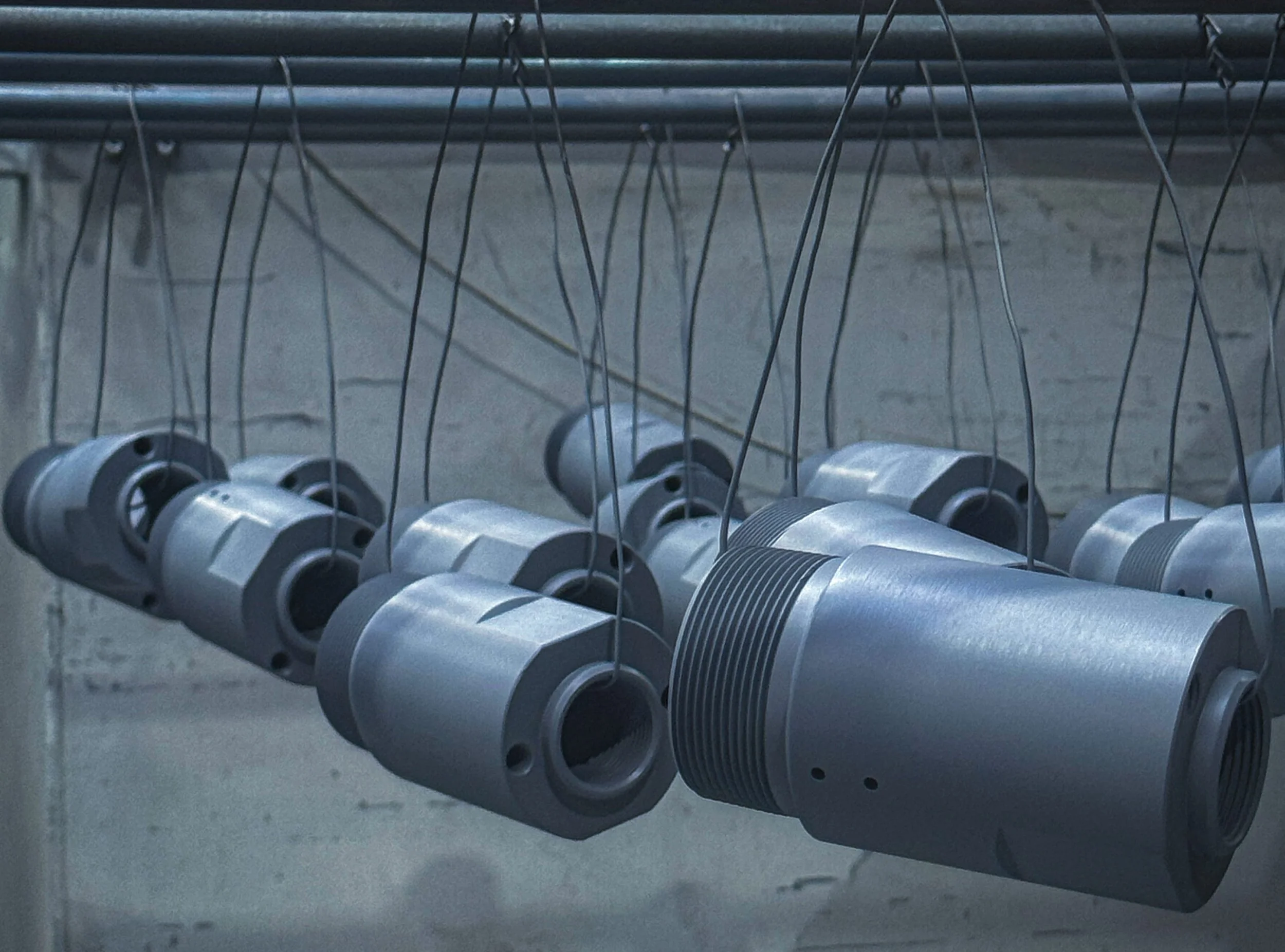

Pipes & piping systems

Downstream pipes, spools, bends, anchors, and tubular joints.

Oilfield & petrochemical equipment

Tanks, skid systems, separators, and pressure vessels.

Construction and infrastructure

Structural steel, screw piles, handrails, kick plates, and containment tanks.

Marine applications

Ships, offshore platforms, and submerged components.

Automotive & agricultural equipment

Gears, pumps, motors, valves, and fasteners.

From small couplings to oversized containment vessels, industrial paintings ensure that critical assets remain functional and protected even in harsh operating conditions.

Types of Industrial Painting Systems

Liquid-based Epoxies

Internal Lining Applications

The application of epoxies is the most common way of protecting fabricated pipe “spools”. Epoxy coatings acts as a barrier to help protect the substrate from corrosion and erosion.

Coatings for Under Insulation

CUI Coatings

These coatings are generally classified as immersion grade epoxies and are designed to operate with the cyclical changes in temperatures under insulation on piping and equipment. Temperature cycles can affect the amount of humidity leading to moisture that may form under the insulation leading to corrosion affecting the substrate.

Epoxy & Polyurethane Systems

These types of coatings are considered to be the most durable of all the above grade coating systems and designed for both functionality and aesthetics. They offer excellent chemical resistance and water resistance. Epoxy coatings are not UV stable and are susceptible to chalking and breaking down over time. They are normally top coated with a UV resistant coating, like polyurethane, when in atmospheric service.

Internal Linings

Pressure Vessels & Tanks

Epoxy coatings used to protect oil treaters, tanks, separators, vessels, or flare knock outs and receiver drums for both immersion and non-immersion. We specialize in coating applications for tanks and vessels that carry acid, downhole chemical “soups”, process water, potable water and oil.

100% Solids Epoxies

Exterior Below-Grade

Applied with a plural component system, 100% solid coatings are primarily used as a coating application for below grade pipelines, pipe bends, fittings, valve assemblies and various below grade equipment. It is also a suitable system to be used on “slip bore” piping where extra abrasion-resistance is required. Learn more about our Underground Gas Pipe Coatings.

Alkyd Primer & Paint Systems

Sometimes referred to as “oil-based” coatings or oleoresins have been in use in one form or another for thousands of years. These primers and paints produce a hard and durable film and are a more economical alternative to epoxy / polyurethane systems. Urethane alkyds do offer enhanced chemical resistance and a harder more abrasion-resistant finish than standard alkyds.

Why Choose Custom Coatings International for Industrial Painting?

With over three decades of expertise, our team specializes in the precise application of industrial painting for oil & gas, petrochemical, marine, automotive, and construction sectors. We prioritize surface preparation, coating selection, and application quality to ensure maximum protection and long-lasting performance, even in the harshest operating environments.

Lets Discuss Your Project

Need help finding the right solution? Contact us below or fill out the contact form and we will have the appropriate customer service specialist contact you.

Industrial Painting FAQs

-

Industries such as oil & gas, marine, construction, and automotive benefit the most due to their exposure to corrosion, chemicals, and heavy mechanical stress.

-

No. They can also be applied during refurbishment projects to extend the service life of older equipment and reduce replacement costs.

-

Lifespan depends on the coating type and service environment. With proper application and maintenance, coatings can last many years, even in extreme conditions.