Polymer Teflon Coating Services

Custom Coatings International is an industry leader in polymer “Teflon” coating applications, protecting equipment from corrosion and harsh environments across Alberta and internationally for over 35 years. Contact us to discuss your project and request a quote.

Trusted Polymer “Teflon” Coating Services for 35+ years

Fluoropolymer coatings—commonly referred to by the trade name Teflon®—are high-performance surface treatments that provide exceptional durability, chemical resistance, and non-stick properties. A polymer Teflon coating is trusted worldwide for its ability to extend equipment life, improve efficiency, and reduce maintenance costs across industries such as manufacturing, automotive, food processing, oil & gas, and medical technology.

With more than 35 years of expertise in industrial coatings, Custom Coatings International has specialized in polymer Teflon coating applications, delivering best-in-class finishes trusted by some of the largest companies in the energy sector and beyond.

Benefits of Polymer Teflon Coating

All types of polymer Teflon coatings provide a wide range of performance benefits, including:

- Non-wetting & anti-fouling surfaces

- Noise reduction

- Unique electrical properties (high dielectric strength)

- Abrasion resistance

- FDA-compliant options (for select coatings)

- Non-stick properties

- Low coefficient of friction

- Heat resistance (up to 260°C / 500°F depending on the coating type)

- Cryogenic stability

- Chemical & corrosion resistance

Types of Polymer Teflon Coatings

PTFE (Polytetrafluoroethylene)

- Highest continuous operating temperature: 260°C / 500°F

- Lowest coefficient of friction among fluoropolymers

- Excellent chemical resistance

- Good abrasion resistance

FEP (Fluorinated Ethylene Propylene Copolymer)

- Maximum operating temperature: 204°C / 400°F

- Flows during baking to form non-porous films

- Outstanding non-stick properties

- Ability to coat complex geometries uniformly

- High chemical resistance and dielectric strength

PFA (Perfluoroalkoxy)

- Maximum operating temperature: 260°C / 500°F

- Tougher than PTFE and FEP coatings

- Excellent chemical resistance

- High dielectric strength

- Forms smooth, non-porous finishes during baking

ETFE (Ethylene Tetrafluoroethylene Copolymer)

- Continuous operating temperature: 149°C / 300°F

- Exceptional toughness and durability

- Excellent chemical resistance due to non-porous film

- Highly protective in demanding environments

Application & Performance in Extreme Environments

Polymer Teflon coatings can be applied using advanced methods such as spraying, dipping, or electrostatic coating, followed by a precision baking process that bonds the coating securely to the substrate. Proper surface preparation—through cleaning, grit blasting, and priming—is essential to ensure maximum adhesion and long-term durability.

One of the most valuable advantages of polymer Teflon coatings is their ability to maintain performance in extreme environments. These coatings remain stable from cryogenic conditions to continuous high-heat exposure up to 260°C (500°F), making them ideal for industries that demand reliable performance in harsh conditions, including oil and gas, food manufacturing, and chemical processing.

Compared with alternatives such as epoxy or ceramic coatings, polymer Teflon coatings offer a unique balance of non-stick functionality, chemical resistance, and low friction that competing technologies cannot match. This combination helps prevent material buildup, reduces energy loss from friction, and ensures equipment runs efficiently with minimal downtime.

Industries We Serve

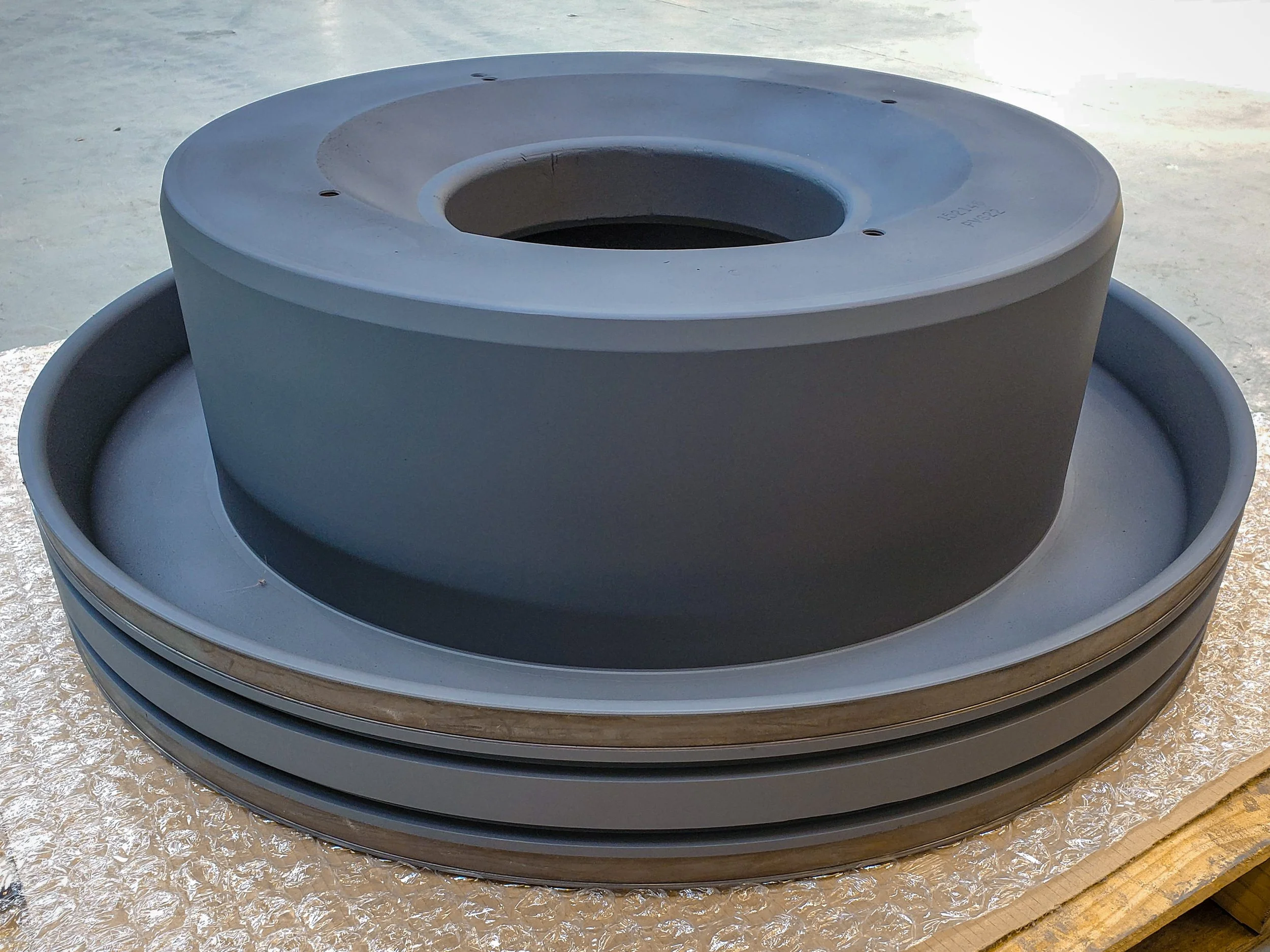

Industrial Equipment

Pumps, valves, bearings, fasteners, diffusers, impellers, inducers, sleeves, nuts, bolts, studs, and more.

Food Processing

Bakeware, conveyor systems, cutting tools.

Automotive & Aerospace

Engine parts, seals, sliding mechanisms.

Medical & Pharmaceutical

Surgical instruments, catheters, lab equipment.

Consumer Goods

Cookware, electronics, household appliances.

Why Choose Our Polymer Teflon Coating Services?

We specialize in precision application of polymer Teflon coatings tailored to your needs. With advanced surface preparation, strict quality control, and expert technicians, we ensure coatings deliver long-lasting performance. Our team provides custom solutions, fast turnaround times, and competitive pricing for businesses across industries.

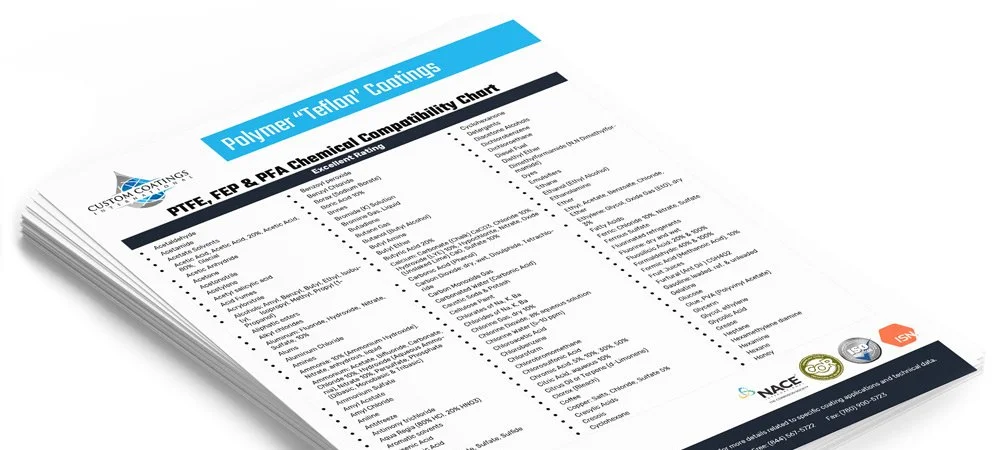

POLYMER TEFLON COATING TECHNICAL DETAILS

For information on different coatings, chemical compatibility and more, download the PDFs below.

Lets Discuss Your Project

Need help finding the right solution? Contact us below or fill out the contact form and we will have the appropriate customer service specialist contact you.

FAQs

-

There is no effective way to spot-repair Teflon (PTFE) coatings. When a Teflon coating is damaged or worn, the most reliable solution is to fully remove the existing coating and reapply a new one. This process typically involves abrasive blasting to prepare the surface, followed by recoating and thermosetting in an industrial oven to ensure proper adhesion and performance.

Depending on the part and application, stripping and recoating Teflon can be a more cost-effective solution than replacing the component entirely.

-

Yes, CCI applies both Xylan and DuPont coatings. CCI specially stocks several types of Xylan coatings in shop, allowing for quick turn around times of parts and components.

-

Custom coatings internation has worked with a variety of industries internationally but has extensive experience in serving the oil and gas industry here in Alberta and expanding out to Wyoming, Oklahoma, California, and markets outside of North America.