HVOF Coating

HVOF coating services deliver high-density, wear-resistant, and corrosion-resistant coatings for industrial components requiring extreme performance. Contact us to discuss your project and request a quote.

HVOF Coatings Overview

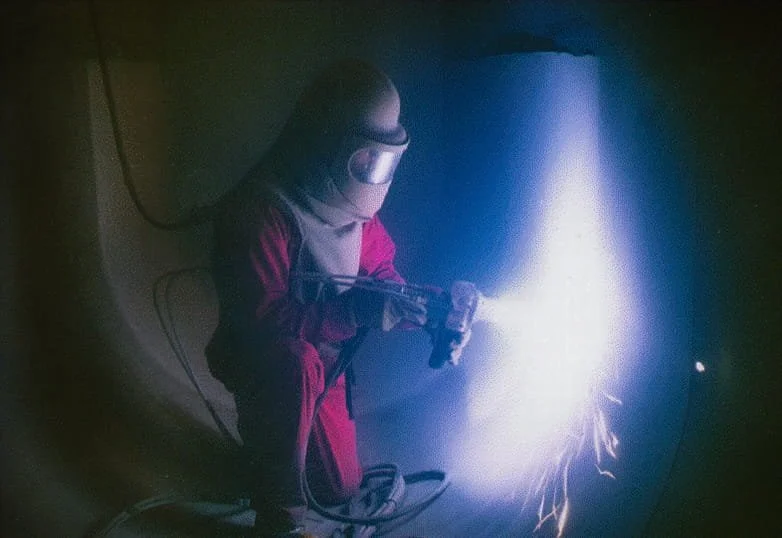

High Velocity Oxygen Fuel (HVOF) coating is a thermal spray coating process used to improve or restore a component’s surface properties or geometry. This surface engineering technique extends equipment life by increasing erosion and wear resistance as well as corrosion protection.

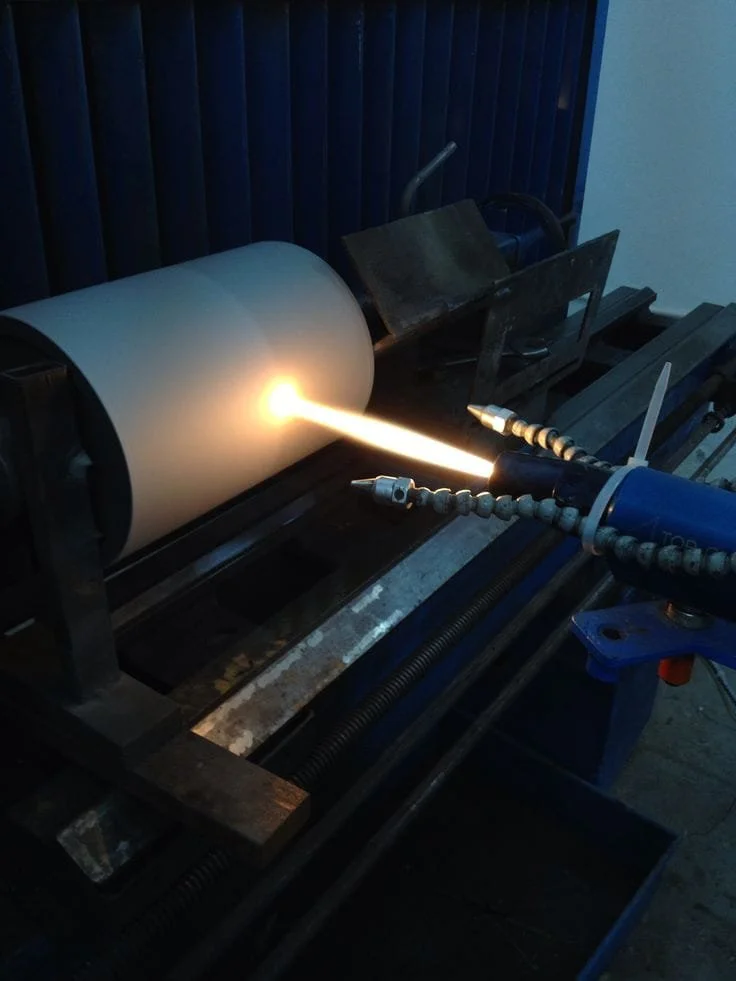

HVOF spraying was developed in the 1980s as a subset of thermal spraying. The process works by mixing fluid fuel and oxygen, which is fed into a combustion chamber and ignited. The resulting gas has an extremely high temperature and pressure, which is ejected through a nozzle at supersonic speeds. Powder is injected into the high-velocity gas stream, where it partially melts and is directed toward the surface to be coated.

HVOF coatings are characterized by a dense structure with low porosity (1–2 vol%), low oxide content (1–2 wt%), and high bond strength (often exceeding 80 MPa). These features provide excellent wear resistance, corrosion protection, and durability.

Common Coating Materials

HVOF spraying supports a wide range of materials, allowing flexibility depending on performance requirements:

- Cermets (e.g. WC/Co, WC/Co/Cr, Cr 3C 2/NiCr, NiCrSiBC)

- Ceramics (e.g. Cr 2O 3, Al 2O 3, ZrO 2)

- Metal alloys (e.g. steels, nickel, chromium and cobalt alloys including NiCrSiB and MCrAlYs)

- Pure metals (e.g. Ni, Cu, Al, Mo, Ti)

- Polymers (e.g. polyester, nylon)

- Composites (e.g. Ni-graphite)

Key Benefits of HVOF Coating

HVOF coatings provide a wide range of mechanical and functional benefits:

- High hardness, durability, and toughness

- Abrasion and erosion resistance

- Corrosion resistance in many environments

- Fretting and anti-galling properties

- Long-lasting traction surfaces

Advantages over other coating methods include:

- Higher density and lower porosity due to greater particle impact velocities

- Higher bond strength and cohesive strength within the coating

- Lower oxide content due to reduced in-flight exposure

- Retention of powder chemistry at high temperatures

- Smoother as-sprayed surfaces

- Superior wear resistance and hardness

- Improved corrosion protection due to reduced porosity

- Ability to build thicker coatings with less residual stress

Applications of HVOF Coatings

One of the most commonly applied coatings is tungsten carbide 86/10/4 (86% Tungsten Carbide, 10% Cobalt & 4% Chromium). Typical applications include:

- Seal areas on shafts

- Ball and gate valves

- Hydraulic rams

- Pump seals

- Industrial components requiring hard chrome replacement

HVOF spraying is primarily used to apply high-quality coatings of cermets such as WC/Co and WC/Co/Cr. Coating thickness typically ranges from 2.0–40.0+ mil DFT (0.002”–0.040”). These coatings enhance the performance of cost-effective, lightweight, or base materials by adding a functional surface layer.

This coating achieves hardness levels of 1200–1400 Vickers and operates effectively at temperatures up to 500°C (932°F). It provides exceptional hardness, wear resistance, and corrosion protection. However, it is not suitable for high-pH environments or hydrofluoric acid solutions.

Lets Discuss Your Project

Need help finding the right solution? Contact us below or fill out the contact form and we will have the appropriate customer service specialist contact you.

HVOF Coating FAQs

-

HVOF coatings are widely used in oil & gas, aerospace, power generation, mining, pulp and paper, and general industrial applications where components are exposed to severe wear, erosion, or corrosion.

-

Yes. While highly durable, certain HVOF coatings (like tungsten carbide) are not suitable for high-pH environments or hydrofluoric acid exposure. Coating selection must match the operating environment.

-

Most HVOF coatings operate effectively up to 500°C (932°F), though performance may vary based on coating material and application.

-

Yes. Tungsten carbide HVOF coatings are often used as an environmentally friendly and higher-performance alternative to hard chrome plating, especially for hydraulic rams, pump components, and valve surfaces.