Fusion Bond Epoxy

Fusion bond epoxy coating delivers superior corrosion resistance and durability for pipelines, steel, and industrial equipment. Located in Alberta, serving internationally, we have been the trusted applicator for industry leaders for over 35 years. Contact us to discuss your project and request a quote.

Fusion Bond Epoxy Coating Overview

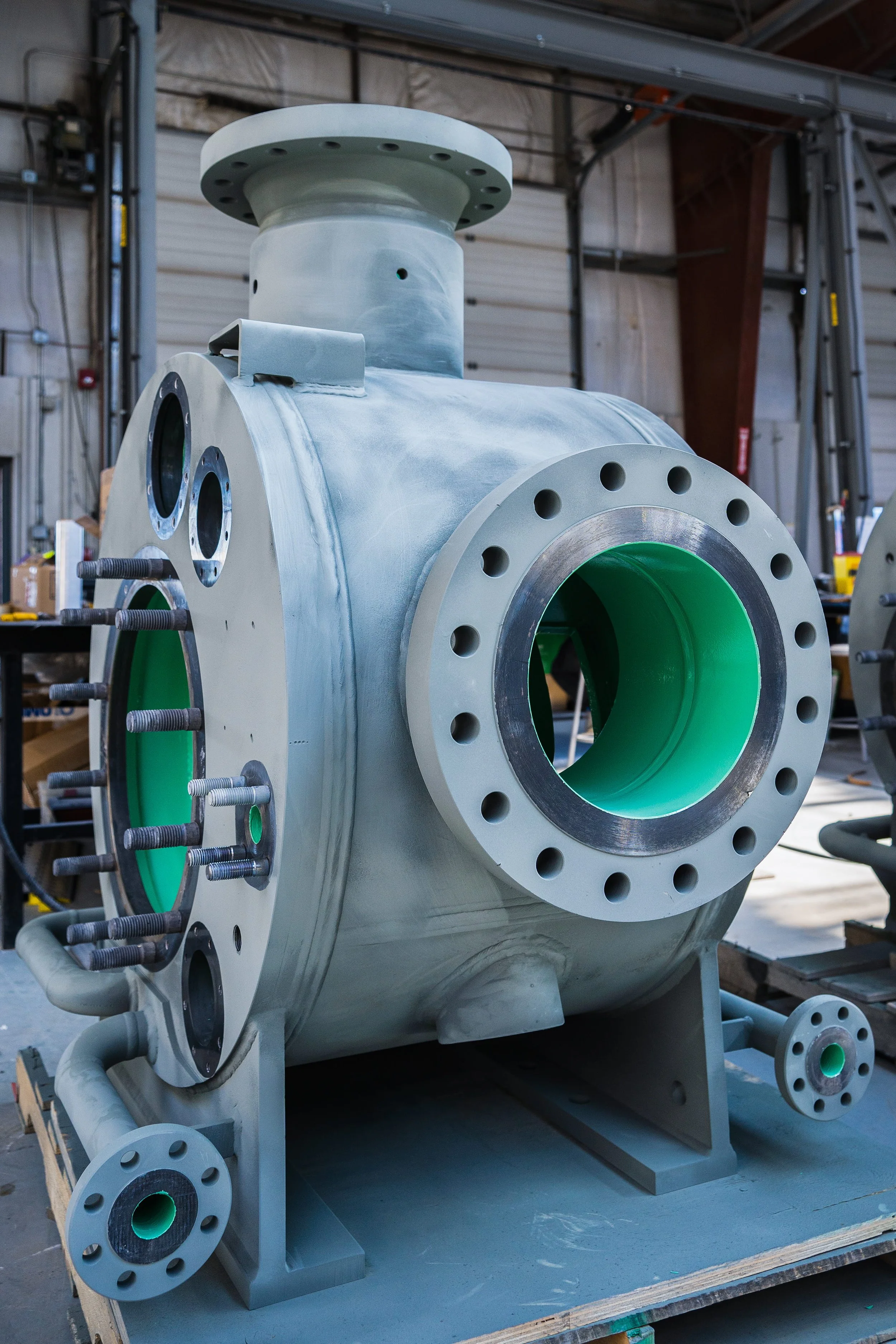

Fusion bond epoxy coating (FBE Coating) is a high-performance protective coating widely used in industries that demand exceptional corrosion and abrasion resistance. At Custom Coatings International Inc., we provide precision-applied FBE coatings for pipelines, construction equipment, valves, fittings, and other steel components that need long-term durability in challenging environments.

About Fusion Bond Epoxy Coating

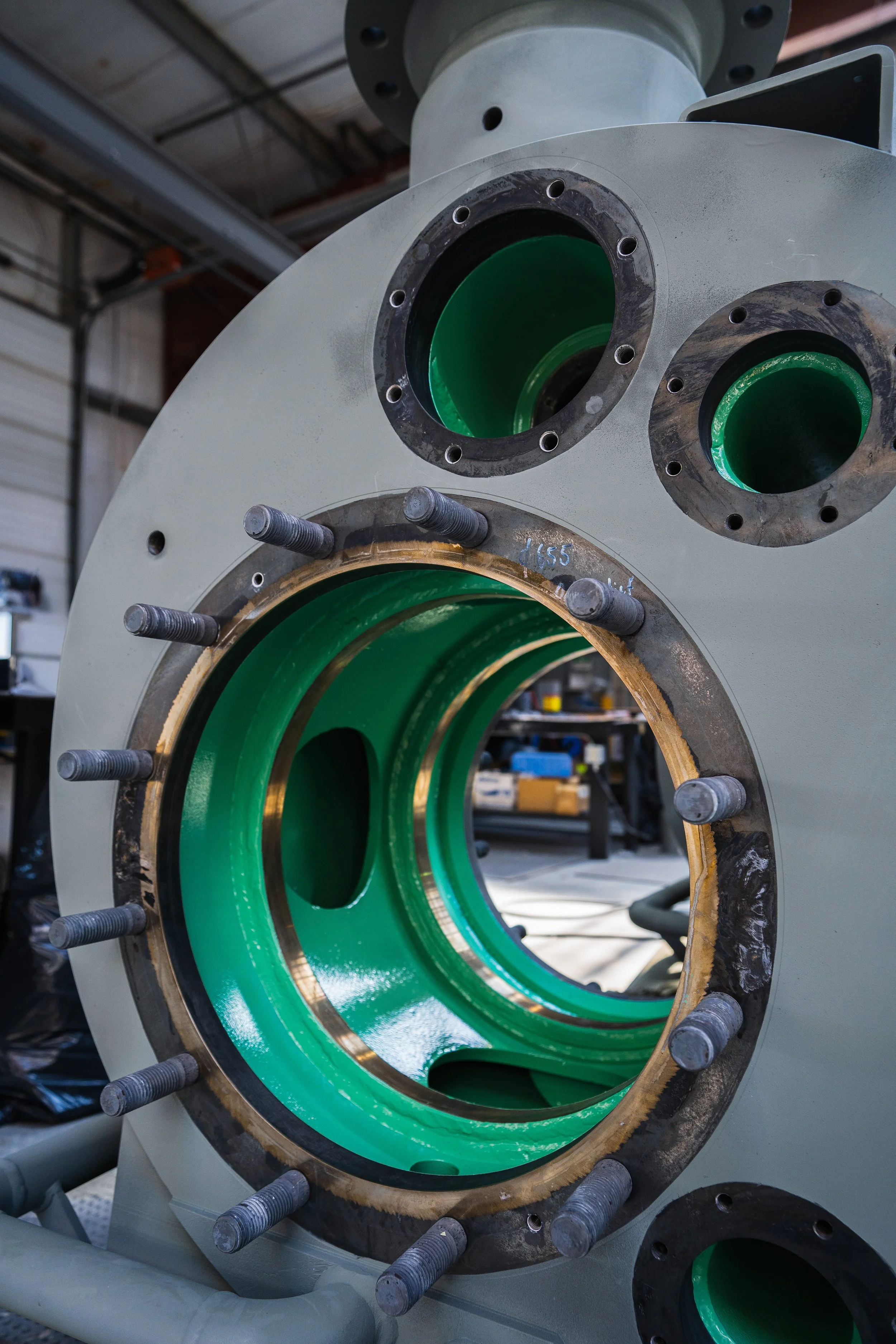

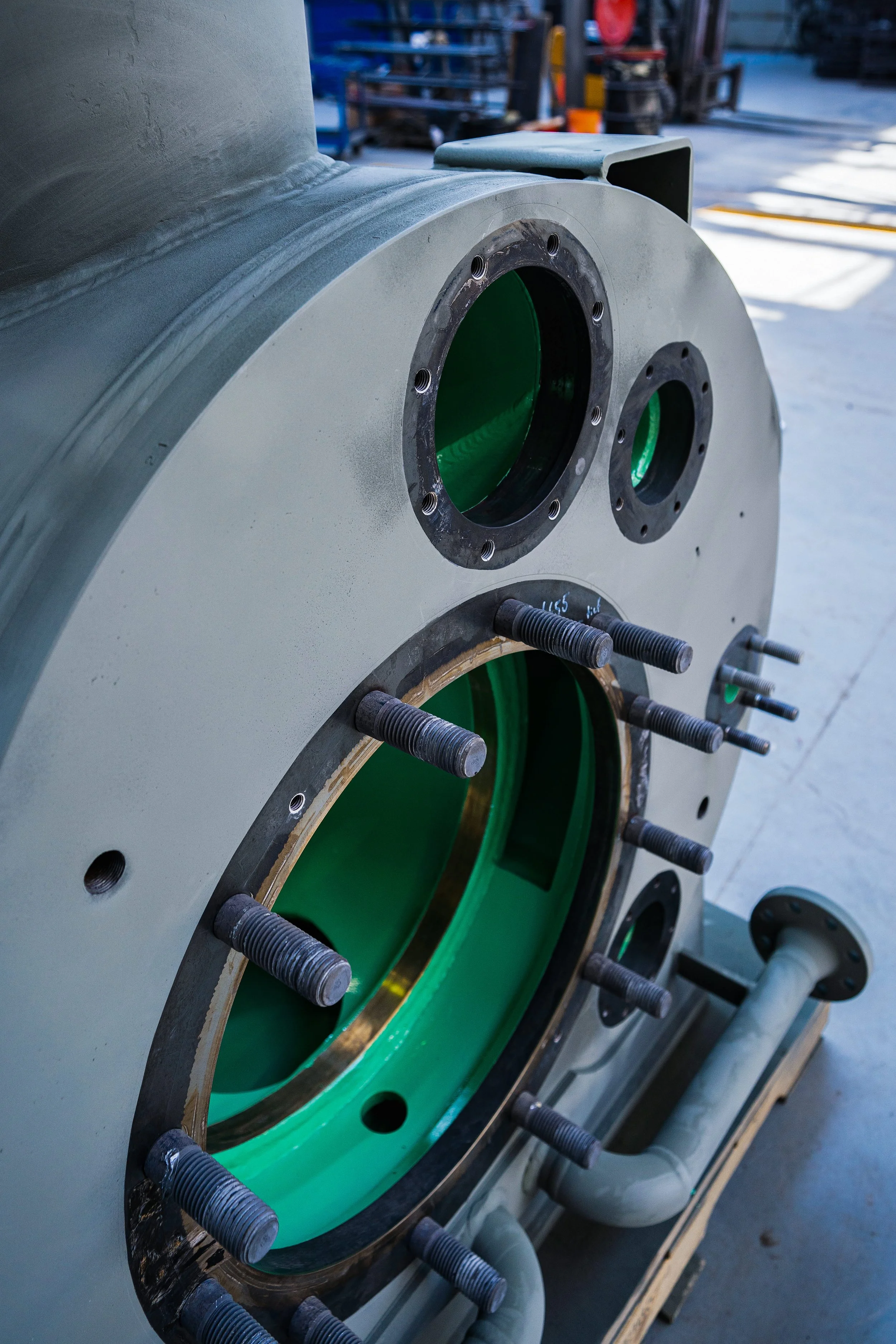

Fusion bond epoxy is a thermosetting powder coating applied to pre-heated surfaces, typically steel. The epoxy powder melts, flows, and chemically cross-links to form a highly durable coating. Once cured, FBE creates a seamless, hard, and protective barrier that resists corrosion, chemicals, and physical wear. This makes it a leading choice for buried or submerged pipelines, oil and gas equipment, and infrastructure that faces extreme operating conditions.

Benefits of Fusion Bond Epoxy Coating

FBE coatings provide a wide range of benefits that extend the life and reliability of critical assets:

- Corrosion resistance → Protects steel from moisture, soil conditions, and aggressive chemicals.

- Abrasion and impact resistance → Withstands handling, transport, and installation stresses.

- Strong adhesion → Bonds directly to metal substrates for long-lasting protection.

- Chemical resistance → minimizes wear on moving components, extending equipment life.

- High temperature performance → Can endure elevated operating conditions without losing effectiveness.

- Environmentally friendly → Contains little to no volatile organic compounds (VOCs).

Applications of Fusion Bond Epoxy Coating

Water & Wastewater Systems

Prevents leaks and corrosion in critical infrastructure.

Oil & Gas Pipelines

Protects buried and submerged pipelines from corrosion and wear.

Construction Equipment

Extends the service life of steel beams, rebar, and structural supports.

Marine & Offshore Applications

Withstands saltwater exposure and harsh offshore conditions.

Valves, Fittings & Couplings

Enhances durability and reliability of mechanical components.

Single-Layer and Multi-Layer FBE Systems

We’re equipped to handle projects of all sizes. Anything from small precision components to large-scale industrial equipment. Our facility includes:

- Single-layer FBE → Provides excellent corrosion protection and mechanical strength for many standard applications.

- Multi-layer FBE → Combines FBE with additional topcoats (such as polyethylene or polypropylene) to enhance resistance against higher temperatures, moisture ingress, and mechanical stress.

Common Industrial Paint Coatings Applications

With decades of experience in industrial coatings, we understand the demands of Alberta’s harsh climate and the rigorous standards of industries like oil and gas, construction, and infrastructure. Our team specializes in fusion bond epoxy applications with:

- Advanced surface preparation techniques

- Precise application and curing processes

- Strict quality control measures

- Fast turnaround times

- Competitive pricing

If you’re looking for fusion bond epoxy coating in Alberta, trust Custom Coatings International Inc. to provide solutions that protect your assets and reduce maintenance costs. Contact our team today to discuss your project needs.

Lets Discuss Your Project

Need help finding the right solution? Contact us below or fill out the contact form and we will have the appropriate customer service specialist contact you.

Fusion Bond Epoxy FAQs

-

When properly applied, FBE coatings can last 20 to 30 years or more, depending on the operating environment and maintenance practices. Buried or submerged pipelines with FBE protection often achieve decades of reliable performance.

-

FBE is most often used on pipelines, valves, fittings, rebar, construction equipment, and marine infrastructure. It is especially valued in oil & gas, water treatment, and offshore applications.

-

Fusion Bond Epoxy coating is thermosetting, meaning that the size of parts is limited to the size of the oven. Currently, Custom Coatings International has a 10’ by 14’ oven, allowing us to work on numerous parts and equipment from numerous industries.

-

FBE is considered environmentally friendly because it contains very low volatile organic compounds (VOCs) and produces minimal emissions during application.