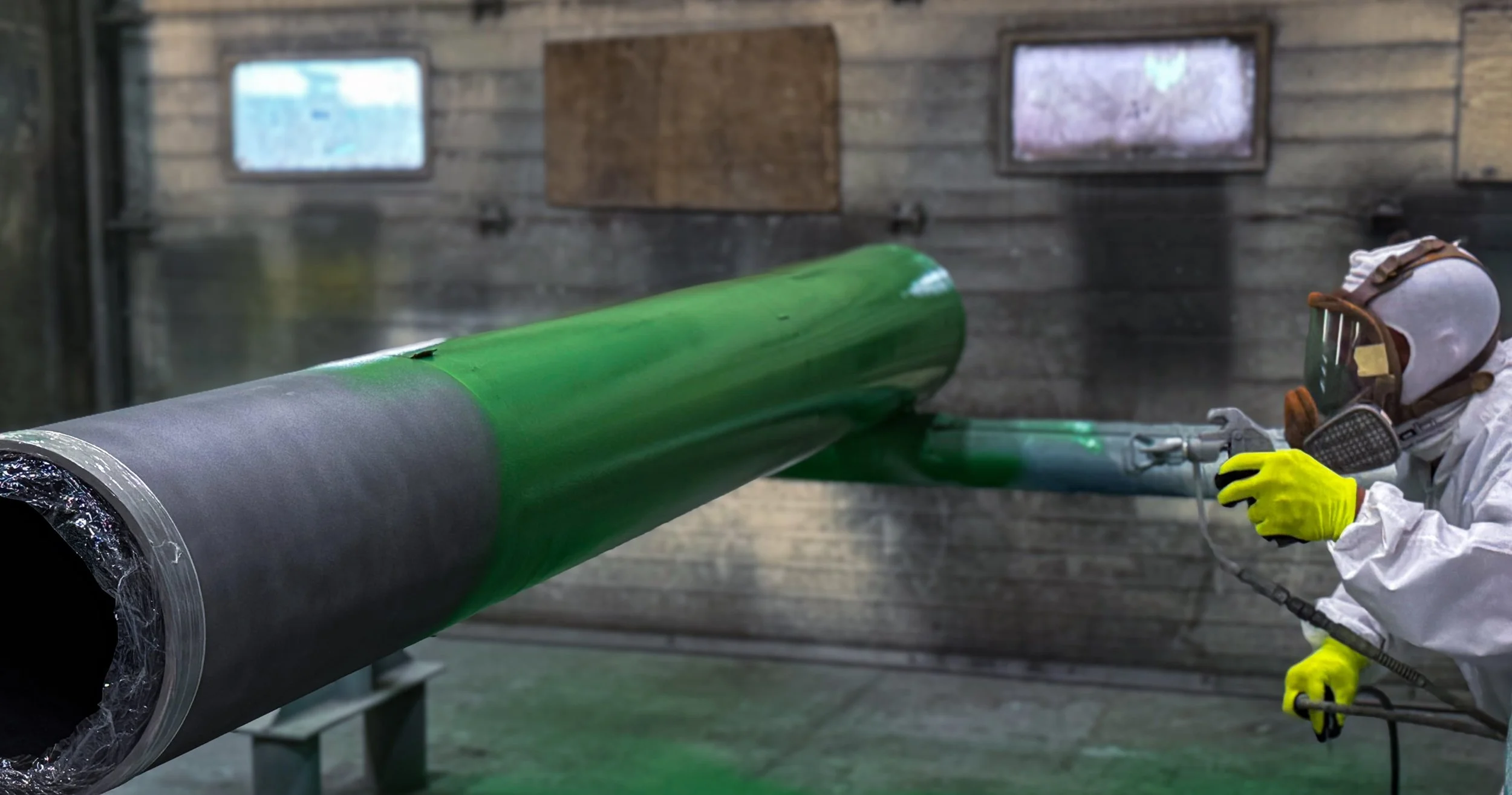

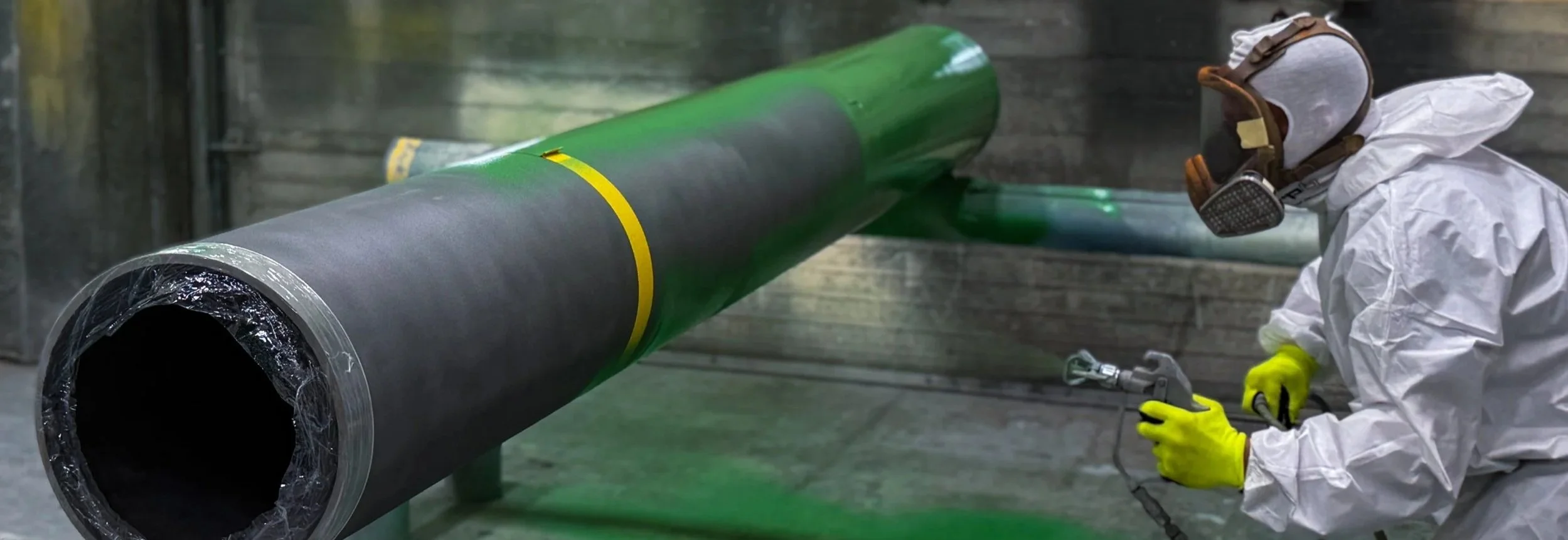

Underground Gas Pipe Coating

Custom Coating International Provides a range of 100% Solid, below grade coatings, helping meet coating specification requirements with precision and quality. For more information, contact us below.

About Our Underground Gas Pipe Coating

Custom Coatings International continually expands its service offerings to meet increasingly stringent project specifications while delivering consistent, high-quality work on time and on budget. As part of our commitment to providing comprehensive protective coating solutions, CCI is a certified applicator of several specialty coating systems, including Denso Protal 7200, ICAT-CEL-375, and Carboline’s SP-2888, SP-3888, and SP-8888, with additional coating systems available upon request.

Underground Gas Pipe Coating Products

Custom Coatings International has been trained, tested, and approved for several specialty coatings.

Denso Protal 7200 Coatings

Denso Protal 7200 is a VOC-free, 100% solids, high-build liquid epoxy coating system. Custom Coatings International is an approved applicator of the Denso Protal 7200 spray-applied coating system in accordance with CSA Z245.30, System FC1 / FC3, Version 1.1. For several decades, Protal 7200 has been widely specified by pipeline materials, corrosion, and integrity engineers due to its proven physical properties, adhesion performance, and reliable cure characteristics. Key performance features include:

- Fast touch dry and set times

- High temperature resistance up to 203°F (95°C)

- High build (up to 70 mils / 1778 microns in one coat)

- Excellent adhesion (compliments FBE coated pipe)

- High abrasion resistance for drilling applications

- Can be used as an abrasion resistant coating (ARO)

- Safe and environmentally friendly

- Does not shield cathodic protection

- Can be applied with brush, roller or spray

- Available in a variety of packaging options

- Meets AWWA C-210 Standard

- Outstanding self-leveling characteristics

- CSA Z245.30 compliant

ICAT-CEL-375 Coating

ICAT-CEL-375 is a 100% solid, high build, pipeline coating with full resistance to cathodic disbondment. It is used specifically to treat construction, rehabilitation of existing pipelines, girth welds, valves, bends & field joints. The full list of coating features includes:

- Quick set / fast turn around times

- High build – up to 60 mils in a single coat

- Grey in colour

- Finish: Gloss

- High abrasion resistance for drilling applications

- Pipeline: New Construction & Rehabilitation

- 100% solids content - VOC Compliant

- Excellent Adhesion and Cathodic Protection

- High Abrasion & Impact Resistance – Excellent for slip bores, directional drilling, etc.

- Provides monolithic membrane protection to the substrate

- Quick return to service

Carboline SP-2888 ® RG

SP-2888 is an epoxy-polyurethane hybrid coating system that provides excellent adhesion and corrosion resistance. The system is commonly specified for internal and external protection of steel piping, valves, fittings, and girth welds in buried or immersed service. Typical applications include pipeline rehabilitation, slip bore installations, and horizontal directional drilling (HDD) crossings.Excellent resistance to cathodic disbonding up to 85˚C (185˚F). Additional features include:

- Excellent adhesion to grit blasted steel surfaces, Fusion Bond Epoxy (FBE), Fiber Reinforced Plastic (FRP) and Polyolefin (PP/PE)

- Excellent abrasion, chemical, water absorption and impact resistance

- Good flexibility

- High build single coat application >50 mils

- 100% solids, Isocyanate free, environmentally friendly & safe

- Easily applied by spray, brush, roller or cartridge

Carboline SP-3888 ® FC

SP-3888 is a specially formulated 100% solid epoxy, designed for repairs of damaged internally and externally Fusion Bond Epoxy (FBE), and other liquid applied pipeline coating. The list of features consist of:

- Excellent resistance to cathodic disbonding up to 95˚C (203˚F)

- Excellent adhesion to grit blasted steel surfaces, Fusion Bond Epoxy (FBE), other epoxies and urethanes

- Fast Cure, quick handling and quick return to service

- Excellent chemical and water absorption resistance

- Excellent wetting properties

- High abrasion and impact resistance

- Easily applied by cartridge dispensers

- 100% solids, Isocyanate free, environmentally friendly & safe

Carboline SP-8888 ®

SP-8888 is a 100% solids coating system engineered to provide exceptional resistance to cathodic disbondment at elevated temperatures, with performance demonstrated up to 150 °C (302 °F). The system is specifically designed for internal lining and external coating of pipes, valves, fittings, and girth welds in immersed service conditions, as well as for slip bore and horizontal directional drilling (HDD) applications. Excellent resistance to high temperature cathodic disbonding up to 150˚C (302˚F). Additional features include:

- Excellent adhesion to grit blasted steel surfaces, Fusion Bond Epoxy (FBE), Fiber Reinforced Plastic (FRP), Polyolefin (PP/PE) and HPCC

- Service Temperature up to 150˚C (302˚F)

- Excellent impact resistance; good flexibility

- High build single coat application > 50 mils

- 100% solids, Isocyanate free, environmentally friendly & safe

- Easily applied by spray, brush, roller or cartridge

Additional Underground Gas Pipe Coating Options

In addition to the systems listed above, Custom Coatings International offers a range of additional 100% solids epoxy coating solutions for pipeline applications upon request. CCI works closely with owners, EPCs, and contractors to ensure coating system selection, application, and quality control are aligned with project-specific specifications and performance requirements.

Request a Quote

To initiate the quoting process, please provide the following information (if available):

• Drawings or isometrics

• Coating specifications

• Operating environment details (temperature range and chemical exposure)

• Project timeline or required completion date

We look forward to partnering with you on your coating project. If you have any questions or require additional information, please contact us by phone or email below.

Underground Gas Pipe Coating FAQs

-

Denso Protal 7200 is a proven liquid epoxy pipeline coating that has been specified across the oil and gas industry for several decades. The system has been used on major pipeline projects, including large-diameter transmission lines such as the Keystone Pipeline. Protal 7200 is commonly specified by pipeline materials, corrosion, and integrity engineers due to its strong adhesion, robust physical properties, and predictable cure characteristics. These attributes make it well-suited for applications such as girth welds, tie-ins, bore joints, and coating repairs.

-

Yes, if an operator-approved topcoat is applied, specifically one with long-term UV protection. Denso’s website recommends using the recommended Archco 65 for UV protection and chalking prevention.

-

Yes. Custom Coatings International has the capability to apply internal pipeline coating systems in accordance with project-specific specifications. CCI is experienced in the internal application of coatings such as Denso Protal 7200, ICAT-CEL-375, and Carboline SP-2888 RG and SP-3888 FC, as well as other underground gas pipeline coating systems when specified.